Environmentally Friendly and Sustainable

Hotbox Studios is very conscious about the impact of the company on the environment and wherever possible minimises this impact.

Working in partnership

Hotbox Studios shares the same office space as it's sister company Hotbox Events thus on a day to day basis many of the same environmental and sustainability policies, procedures, and practices...

How we reuse and recycle

We save and reuse packaging, signs, we look after equipment by cleaning and fixing it rather than replacing it.

We recycle everything we can, so paper, cardboard, cans, glass, plastics, ink cartridges...

How we reduce

Since 2000 we've been working with our clients helping them to provide paperless systems which are used by millions every year.

We offer digital documents such as info packs, contracts, manuals, statements, fact sheets and invoices wherever possible to avoid unnecessary printing and paper use.

Thinking outside the...HeatBox

We're always looking for innovative ways to reuse, recycle, and reduce...

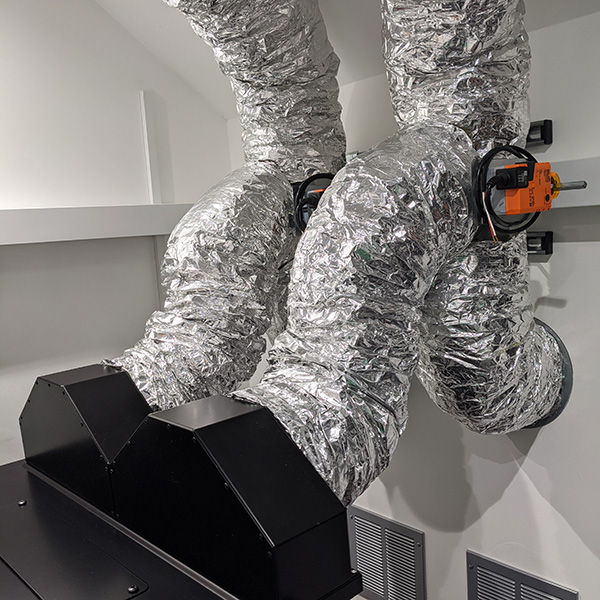

For example, we've designed and built a custom system which reuses the heat generated by our company's IT equipment for heating the open-plan areas of the Hotbox Studios and Hotbox Events office.

On colder days, rather than the heat generated by the IT equipment housed in our server cabinet being pushed out into the environment thus wasted, this heat is ducted into the open-plan office areas.

The reuse of this heat has reduced the energy we use for heating the office by 50%.

In addition to the ducting and actuators pictured, we've designed a control unit called HeatBox which monitors the temperature outside of the office and automatically redirects the heat being generated as required. On colder days the heat is directed into the office, on warmer days it's directed out.

So although on warmer days the heat being generated isn't reused, due to the heat controlled nature of our system and unlike an open cabinet setup; separating the warm exhaust air from intake air means energy is not being wasted cooling warm exhaust air before it reenters the cabinet.

Intake air is a combined fresh air and AC solution, meaning unless the outside temperature is very warm; naturally cool intake air is used offering a further energy saving over traditional AC cooling models.

Where our energy comes from

The energy we use is from the UK's leading generator of renewable energy.

Renewable energy isn't a new thing for them - they've been investing in cleaner energy sources for over 50 years.

Our supplier built the world's first deep water wind turbine in the Moray Firth, their wind farm in Ayrshire the first in the UK to generate 100MW of electricity and their new Glendoe hydro station at Loch Ness being Britain's most efficient.

How we source and maintain

Whenever we need to replace electronic equipment we do so with the most up-to-date and energy efficient we can source. Our main supplier has been building environmental considerations into every stage of the product life cycle - development and design, manufacturing, operations, customer use, end-of-life product disposition - for more than 20 years.

All of our electronic equipment is protected from power spikes, surges, and failures. In the case of our more critical systems there is also secondary backup power independent of the national grid. This protects the equipment from power related failures, avoiding unnecessary waste and replacement. The protection also avoids data loss and downtime which in turn saves both us and our clients time and money, equating to a saving in energy.

Get in touch

If you have any suggestions about more we could do to be as sustainable a company as possible please don't hesitate to get in touch!

We reuse the heat generated by our company's IT equipment for heating the office!